- For any of your Cables & Cable Management System requirement.

LT Power & Control Cable

LT Power & Control Cable

LT power and control cables, also known as low tension power and control cables, are electrical cables designed for use in low voltage applications. These cables are commonly used in various industries, buildings, and infrastructure projects to transmit power and control signals.

Here are some key features and characteristics of LT power and control cables:

Voltage Rating: LT cables are designed for low voltage applications, typically up to 1 kV (kilovolt) or below. They are suitable for transmitting power and control signals in residential, commercial, and industrial settings where high voltage is not required.

Conductor: The conductors in LT cables are typically made of copper or aluminum. Copper conductors offer better conductivity and are more commonly used in LT cables. Aluminum conductors are used in some applications where weight and cost considerations are important.

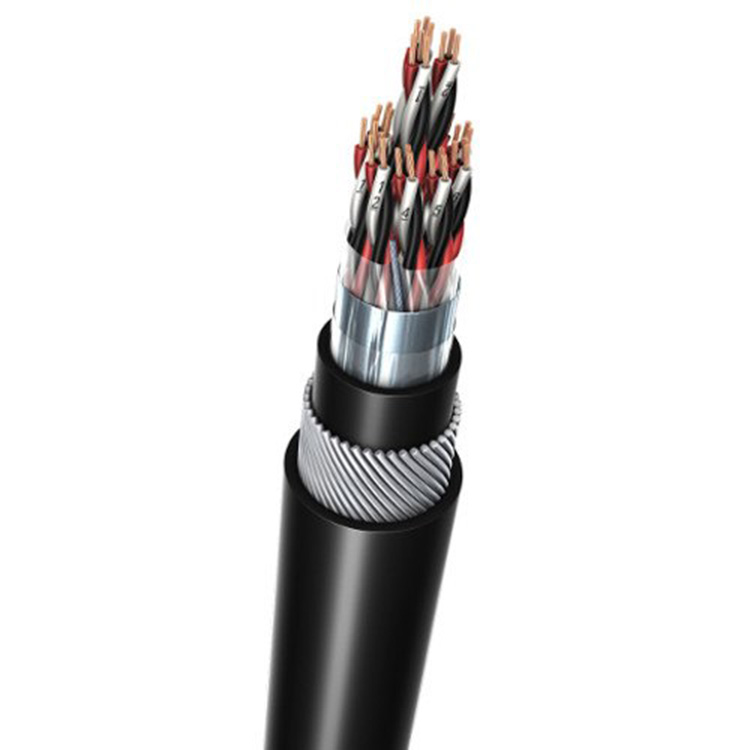

Insulation: LT cables have multiple layers of insulation to provide electrical insulation and protect the conductors. The insulation materials commonly used include PVC (Polyvinyl Chloride), XLPE (Cross-Linked Polyethylene), or EPR (Ethylene Propylene Rubber). XLPE is preferred for its superior electrical and thermal properties.

Shielding: In some cases, LT power and control cables may feature shielding to protect against electromagnetic interference (EMI) and ensure signal integrity. The shielding is typically made of aluminum or copper, and it can be in the form of a metallic foil or a braided wire.

Core Configuration: LT cables can have single-core or multi-core configurations. Single-core cables consist of a single conductor surrounded by insulation, while multi-core cables have multiple conductors insulated from each other. Multi-core cables are commonly used for applications requiring separate control signals or multiple power circuits.

Armoring: In certain scenarios where mechanical protection is necessary, LT cables may be armored with steel wires or tapes. Armored cables provide additional strength and resistance against physical damage, making them suitable for underground installations or areas with high mechanical stress.

Sheathing: LT cables have an outer sheath that protects the internal components from moisture, chemicals, and mechanical damage. The sheath is typically made of PVC, LSZH (Low Smoke Zero Halogen), or other suitable materials depending on the specific application requirements.

LT power and control cables are available in various sizes, configurations, and insulation types to meet different installation and operational needs. It’s important to select the appropriate cable based on factors such as voltage requirements, environmental conditions, mechanical stress, and regulatory standards to ensure safe and reliable electrical connections.